Does Yovog Household Appliances have agents in foreign countries?

2019-07-07

Dongguan EDS Electronic Technology Co., Ltd has developed the business in a brand-new way and has won many honorary qualifications in the industry. Now we enjoy a large influence in the industry. EDS is located in the area with traffic convenience, which is good for timely delivery of the products. EDS could customize comprehensive and efficient solutions according to customers' different needs. If customers don't have the design, we can design and produce the exact that they want in every detail.

What are the processes and features of ultra-pure water equipment in the electronics industry? Process of ultra-pure water equipment in Electronic Industry 1. ion exchange method is adopted,The process is as follows: raw Water → raw water primary pump → multi-media filter → activated carbon filter → water softener → precision filter → Yang resin filter bed → Yin and Yang resin mixed bed → micro-pore filter → water point 2, using secondary reverse osmosis,The process is as follows: raw water → raw water primary pump → multi-media filter → activated carbon filter → water softener → precision filter → Primary reverse osmosis → PH regulation → intermediate water tank → secondary reverse osmosis (positive charge on the surface of reverse osmosis membrane) → pure water tank → pure water pump → micro-pore filter → water point 3. EDI method is adopted,The process is as follows: raw Water → raw water primary pump → multi-media filter → activated carbon filter → water softener → precision filter → Primary reverse osmos

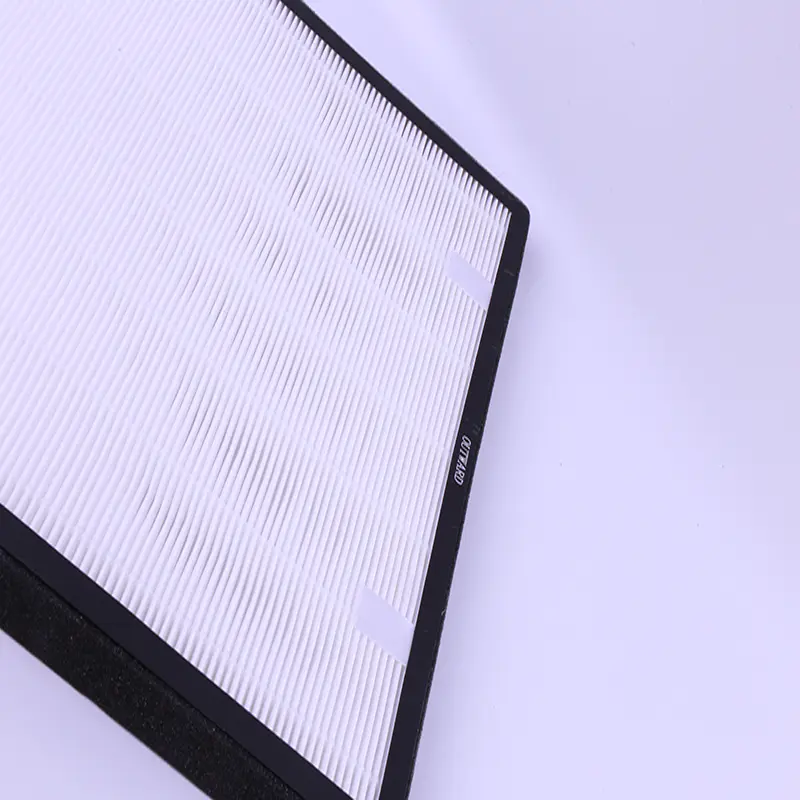

Filter height of mechanical filter The adaptive high-efficiency mechanical filter adopts the adaptive fiber filter as the core application technology,The filter material used is based on the principle of theoretical physics-Nonlinear scientific fractal structure,The advantages are self-adaptive and fractal structures.It not only has the efficient filtration accuracy of the fiber filter material,It also has the advantages of using the particle filter material backwashing cleanliness and small water consumption,The pore distribution of the filter bed formed by using this filter material is basically close to the ideal filter layer structure,When filtering, the filter material will gradually decrease from large to small along the direction of water flow,The distribution of void ratio in the same section is relatively uniform,The water flow is consistent in size when filtering.When filtering,Due to the poor proportion of core and fiber strands,The core plays a role in the compression of the fib

What are the processes and features of ultra-pure water equipment in the electronics industry? Process of ultra-pure water equipment in Electronic Industry 1. ion exchange method is adopted,The process is as follows: raw Water → raw water primary pump → multi-media filter → activated carbon filter → water softener → precision filter → Yang resin filter bed → Yin and Yang resin mixed bed → micro-pore filter → water point 2, using secondary reverse osmosis,The process is as follows: raw water → raw water primary pump → multi-media filter → activated carbon filter → water softener → precision filter → Primary reverse osmosis → PH regulation → intermediate water tank → secondary reverse osmosis (positive charge on the surface of reverse osmosis membrane) → pure water tank → pure water pump → micro-pore filter → water point 3. EDI method is adopted,The process is as follows: raw Water → raw water primary pump → multi-media filter → activated carbon filter → water softener → precision filter → Primary reverse osmos

Filter height of mechanical filter The adaptive high-efficiency mechanical filter adopts the adaptive fiber filter as the core application technology,The filter material used is based on the principle of theoretical physics-Nonlinear scientific fractal structure,The advantages are self-adaptive and fractal structures.It not only has the efficient filtration accuracy of the fiber filter material,It also has the advantages of using the particle filter material backwashing cleanliness and small water consumption,The pore distribution of the filter bed formed by using this filter material is basically close to the ideal filter layer structure,When filtering, the filter material will gradually decrease from large to small along the direction of water flow,The distribution of void ratio in the same section is relatively uniform,The water flow is consistent in size when filtering.When filtering,Due to the poor proportion of core and fiber strands,The core plays a role in the compression of the fib